There is an entire hobbyist scene around it. Go around to your local hackerspace to find out more about it. Either way it will become a big industry once the printers and the material start being affordable and better quality. All the little doo-dads that are currently being shipped from China? Just print them. A case for your iPhone? Print it! The material will still come from China but it will be pure plastic so less transportation costs.

Like copiers and printers back in the day, remember when you had to go to a copy shop for your class project? These days you just print multiples at home because it's cheap.

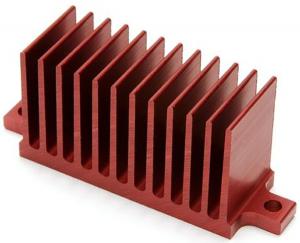

3D printing is just like regular printing but instead of 2D (flat) you're printing things in the 3rd dimension by simply layering materials. It's usually plastics (various types including ABS and PVC) but more expensive laser-driven models can also "print" (it's technically fusing) metals like steel, gold etc and even electronic circuits.

As far as software, there is plenty of free and open source software for it, most 3d printers are actually open designs which can replicate most of their own parts (except for the motors and metal parts)